Plastic Injection Molding

We have 50 years of experience in Plastic Injection Molding and create products across several industries.

We can deliver custom solutions tailored to your specific needs, no matter how complex. From design to prototype to production runs, we are committed to delivering results that exceed your expectations, and keep your project on track.

We can use a variety of processes, technologies, and materials to put your designs into the hands of your customers. Our product portfolio and history is vast and we look forward to bringing your designs to life.

UTP Solutions utilizes Scientific Injection Molding principles and automation in our 90,000sq. ft. facility, wherever possible. Our presses (19) range from 22T - 950T and we have the ability to perform Clean Room Molding, high temperature molding, and Validation if your project requires it.

Common solutions we provide to our customers:

2-shot (2K) / multi-material / multi-color molding with auxiliary equipment and dedicated presses with rotary platens

Insert Molding and Over-molding

Micro Molding and Micro Insert Molding

Nitrogen Gas Assist

Color Match and Mold in color

Design for Manufacturability / Moldability

Design for Reliability

Reduce weight / increase strength

Chemical and UV Resistance

Electrical Insulation

Reduce vibration

Integrate seals / soft touch features

Working hinges

-

Commodity & Engineering Plastic Resins:

Polypropylene (PP)

Polyethylene (PE)

Polycarbonate (PC)

Acrylonitrile Butadiene Styrene (ABS)

High Impact Polystyrene (HIPS)

Acetal (POM)

Polyamide (Nylon) w/ glass filled content

TPO / TPE / TPU

We also have extensive experience in High Performance resins, including:

Polyetheretherketone (PEEK)

Polyphenylsulfone (PPSF PPSU)

Bioresorbable / Biocomposite

Injection Molded Ethyl Vinyl Acetate (EVA) Foam

Non-exhaustive list

ISO Class 8 Clean Room

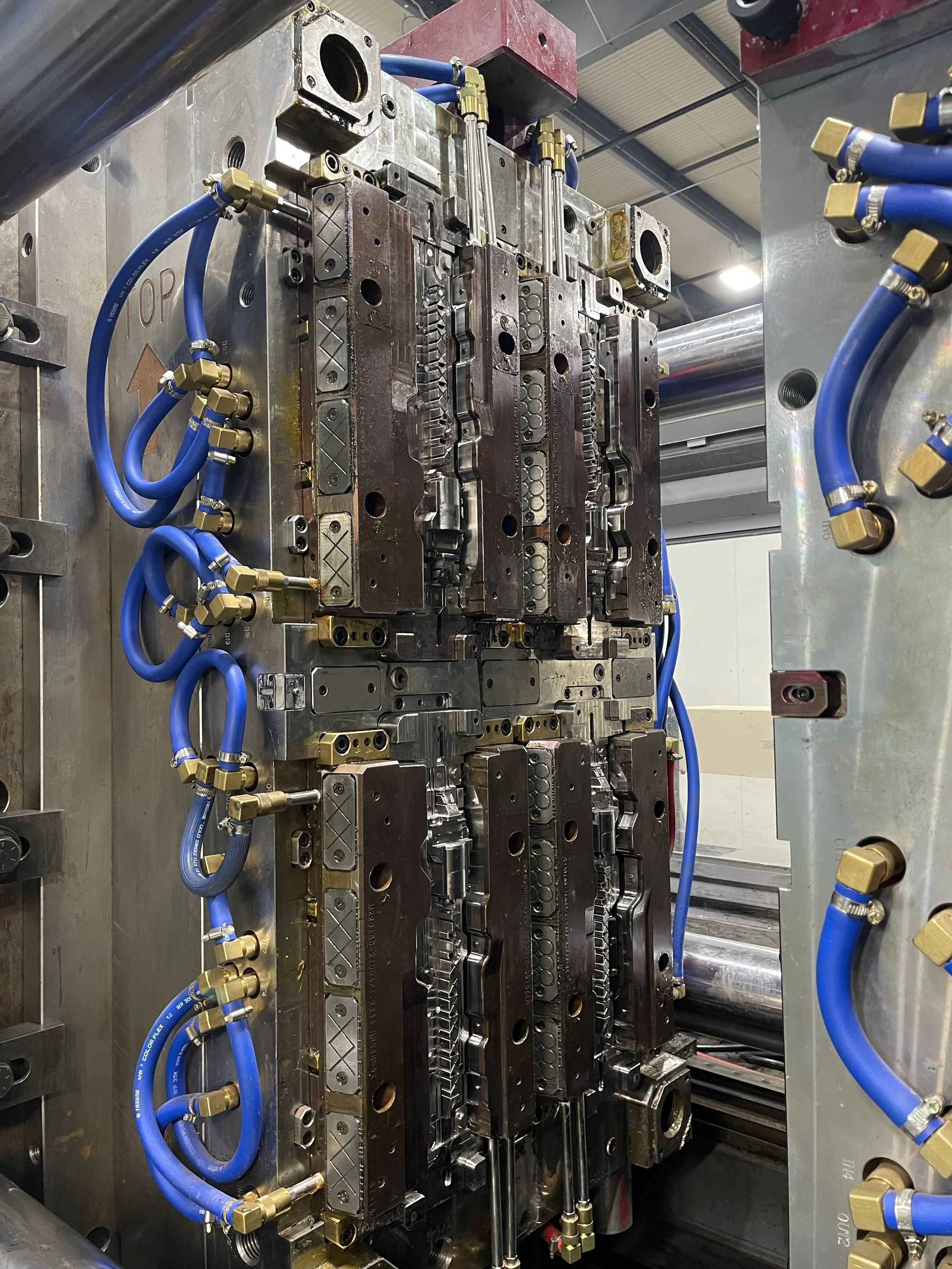

950T Tool 4-Cavity Safety Critical Component

Plastic Manifold

Machined Plastic Exterior Trim Component

Electronics Sensor Holder

Electrical Housing Assembly with Living Hinge

Mold in color and Color Match Components

950T High Cavitation Injection Mold Tooling

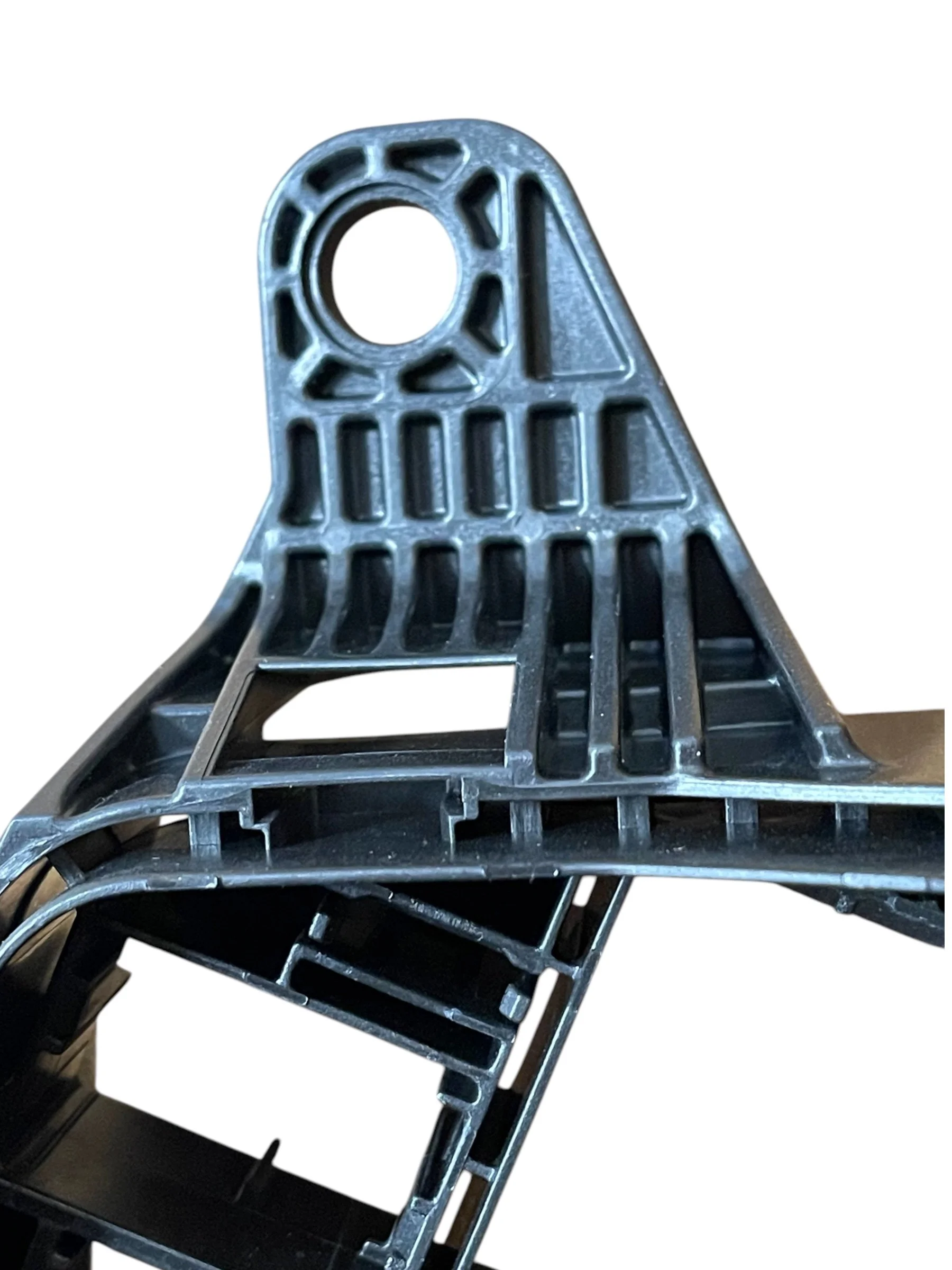

Close-up of a black plastic car roof rack mount with a circular hole and multiple ridges and slots for mounting.

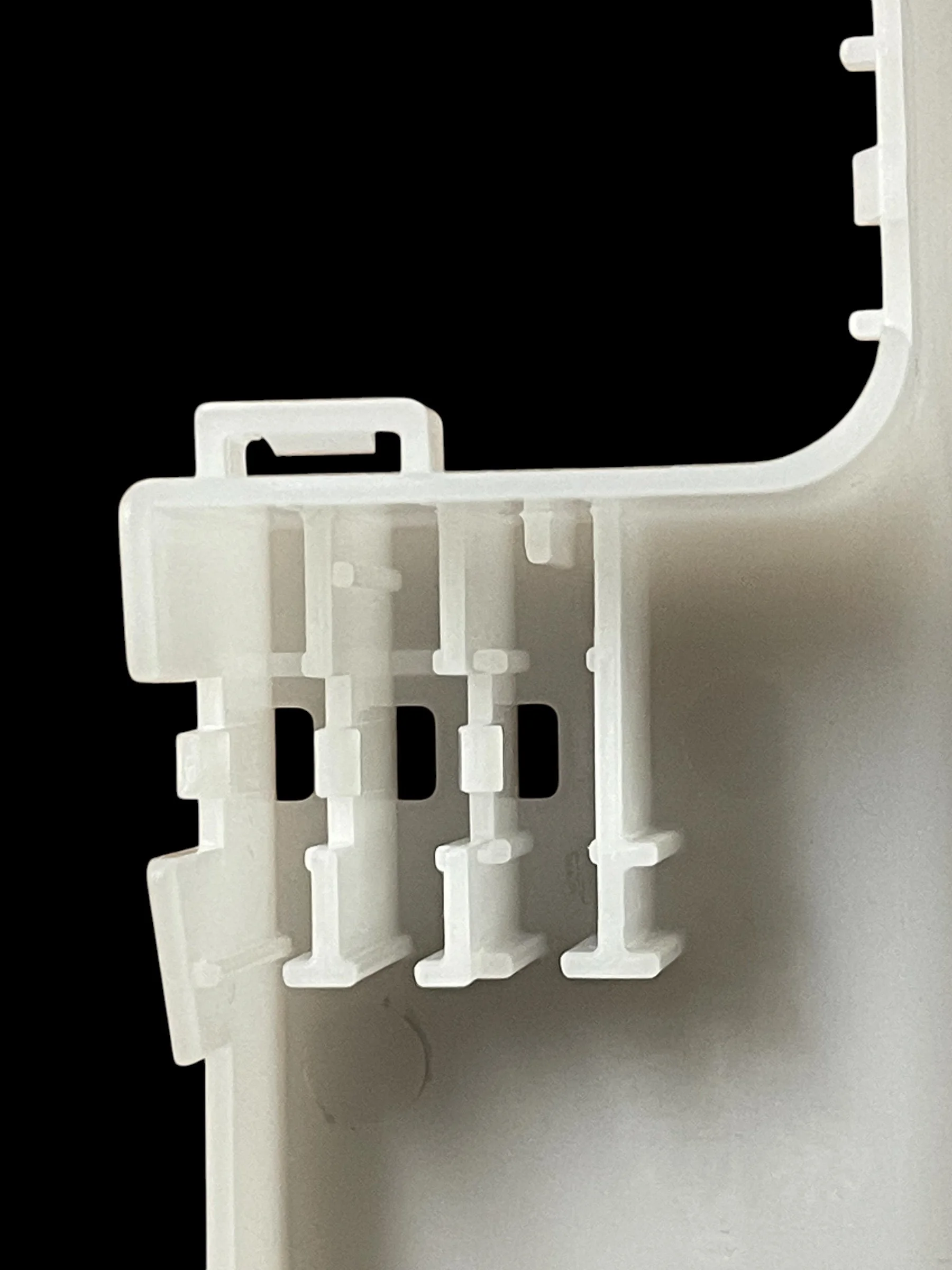

Close-up view of a white plastic component with multiple slots and a small protruding handle against a black background.

Glass Filled Nylon Fan for Heavy Truck application, Insert Molded with balanced cavities for stability and vibration control

Exterior Trim Assembly with Clips and Grommets

2 Shot component (PC ASA and TPE)

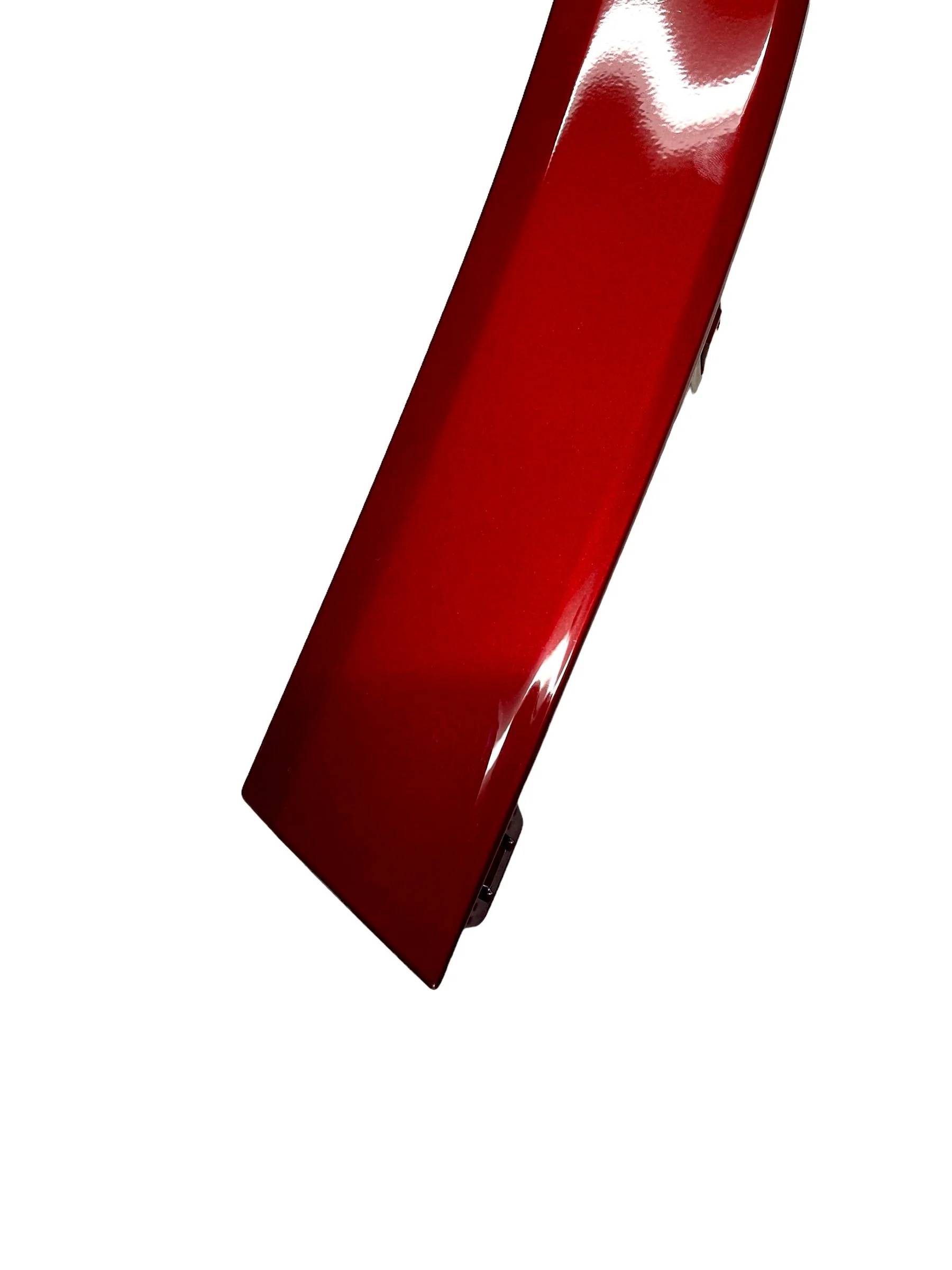

Painted Exterior Trim

102T Arburg Vertical Injection Molding Press for Stylet and Cannula manufacturing

Medical Component

Flocked Interior Trim Compartment

Flocked Interior Trim Component

Medical Device Plastic Injection Molded Component

Leather Wrapped Hand Rail

Acura NSX Leather Wrapped Center Console component

Acura NSX Leather Wrapped Center Console component

Acura NSX Leather Wrapped Center Console component

Mercedes Maybach Painted Exterior Trim Component

Mercedes Maybach Painted Exterior Trim Component

Mercedes AMG Mold in Color Components

Electronic Sensor holder

Electronic Sensor Holder

Interior Trim Component

PC and ASA Component Acura NSX with Painted surfaces

PC and ASA Component Acura NSX with Painted surfaces

PC and ASA Component Acura NSX with Painted surfaces

D Pillar Exterior Trim system utilizing a 2 Shot injection molding process with integrated seals and painted surfaces

Insert molded hand rail with gas assist molding process

Insert molded hand rail with gas assist molding process

A Pillar Exterior Trim system utilizing a 2 Shot injection molding process with integrated seals and painted surfaces

A black plastic automotive part with various holes and mounting points, isolated on a white background.

Insert molded hand rail with gas assist molding process

Insert molded hand rail with gas assist molding process

Lens component

Glass Filled Nylon Fan for Heavy Truck application, Insert Molded with balanced cavities for stability and vibration control

Glass Filled Nylon Fan for Heavy Truck application, Insert Molded with balanced cavities for stability and vibration control

Glass Filled Nylon Fan for Heavy Truck application, Insert Molded with balanced cavities for stability and vibration control

Injection Molded Ethylene Vinyl Acetate (EVA) Storage Bin

Injection Molded Ethylene Vinyl Acetate (EVA) Storage Bin